Choose the Right PTO Shaft for Your Tractor

Selecting the correct power take-off (PTO) shaft – also known as a drive shaft or k-shaft – is crucial for the safe and efficient operation of your implements. Whether you're using a mower, snow blower, manure spreader, or other PTO-driven equipment, Sagroparts will help you find the right model. Here's what you need to consider.

1. Horsepower – match the shaft to your tractor’s output

Start by looking at how many horsepower (HP) your tractor delivers – or how much power the implement requires. We generally recommend choosing a PTO shaft that matches your tractor’s output, not just the implement's. This ensures a flexible solution that supports multiple implements without becoming a limiting factor.

2. Splines – check the connection size

Check what type of splines (teeth) are on your PTO and the implement input. Common sizes include:

- 1 3/8"" – approx. 35 mm outer diameter (most common on small and medium tractors)

- 1 3/4"" – approx. 44.5 mm outer diameter (for larger tractors and machines)

The correct coupling is critical for both fit and safety. Missing the right size? At Sagroparts, you'll find adapters, angle joints, and complete couplings.

3. Standard or wide-angle – how much flex is needed?

A standard PTO shaft typically allows about 5° of working angle. If your implement needs more flex – due to height differences or movement – we recommend a wide-angle shaft. These can handle up to around 25° under load, providing longer lifespan and smoother operation.

4. Safety clutch – do you need a shear bolt or overrunning clutch?

Depending on the implement, you should select the right type of safety clutch. Examples include:

- Shear bolt: Protects the shaft and machine if something jams. Common for snow blowers, where a stone can cause sudden stoppage. The bolt breaks – and the shaft continues spinning without damage.

- Overrunning clutch: Allows the implement to spin freely after the PTO is shut off – important for rotating mowers and similar equipment.

- Friction clutch: Reduces wear by absorbing torque spikes during start and stop.

At Sagroparts, we offer shafts with various clutch types – ready to meet your needs.

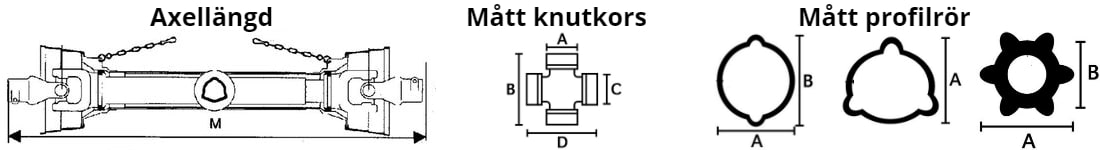

5. Correct length – measure the distance between tractor and implement

PTO shafts are telescopic but must be the right base length to operate safely. As a rule of thumb, inner and outer tubes should overlap at least two-thirds of their length when extended.

Is the shaft too long? You can cut the profile tubes. We recommend trimming from the outer ends – it reduces the risk of burrs and jamming. Measure carefully before cutting, and ensure the guard still fits afterwards.

Extra tips when choosing a PTO shaft:

- Replace universal joints in time – play or vibration indicates wear.

- Grease the shaft regularly, especially during heavy use.

- Always use protective guards – for your safety and to extend lifespan.

Whether you need a new PTO shaft for your tractor, spare parts like U-joints, or a complete PTO kit – Sagroparts is here to help. We'll guide you based on your machine, implement, and working conditions.

Order online – or contact our support team for fast, expert assistance.